Letter to my supervisor about my experiments

Dear Farid,

Today I had a conversation with Daniel and Jim about my experiments and I have a suggestion. As we previously talked together, I should know the ressidual stresses of the surface of the specimens before cutting. I would pick a normalized steel for working with these experiments. I will know the properties of the material and I can anticipate its behaviour. I mean, it is difficult to expect the behaviour of a titanium material. Before I start to research the dependance of the strains on the diameter of the drills (using various diameters of drills), I need to know the ressidual stresses of the surface, because there might be various residual stresses:

I will use the same drill when drilling into the different materials and I will also maintain the same conditions. So I will have the same:

- Cutting conditions,

- Material – which is normalized and have the same properties,

- Gauges,

- Drill,

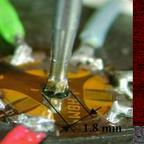

- I will measure it in the CNC machine where the drill hand is , it must be very precise, becase the hole in the centre is very small, but by using CNC, it can be very precise.

I will pick a small piece of material (in order to place one gauge) and then I will place a gauge in the centre of it. Then, by using CNC, I will drill a hole. I will do this with all 6 pieces of material and then I will compare values and see how the values vary.

If the values vary by, lets say, 2-5%, it is ok, and I can start doing experiments as mentioned above (dependance diameters of the drills on the strains). At the end of these experiments, I will write the conlusion that there is a deviation of …. (the value I find out by suggested experiment).

Please, write to me what you think about it.

Regards,

Jarda